16 years of rapid prototyping experience

Cooperation with more than 50 foreign companies

Over 30,000 projects completed

Manufactured 400,000+ prototypes

What can AARS provide you and your

business with our rapid prototyping service?

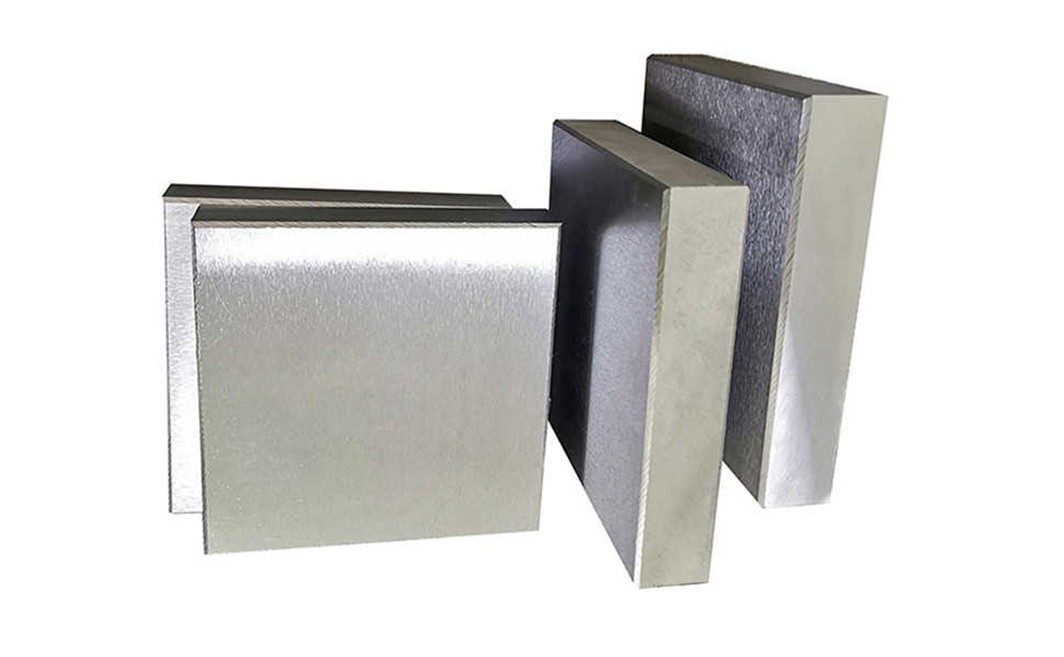

It is the most widely used non-ferrous metal structural material in the industry. As a soft, lightweight and durable metal material, it is often used in aerospace, automobile, machinery manufacturing, shipbuilding and industrial development. The customized aluminum products processed by AARS Smart Tech. have a wide range of appearance and color options and a complete range of surface treatments, which can meet the needs of different industries.

Stainless steel has the characteristics of corrosion resistance, high temperature resistance and ultra-low temperature resistance.It has a wide range of applications and can be used to manufacture medical equipment, auto parts, industrial products, etc. AARS Smart Tech. can provide a variety of stainless steels such as 201, 202, 303, 304, 316, 4130, 4140.

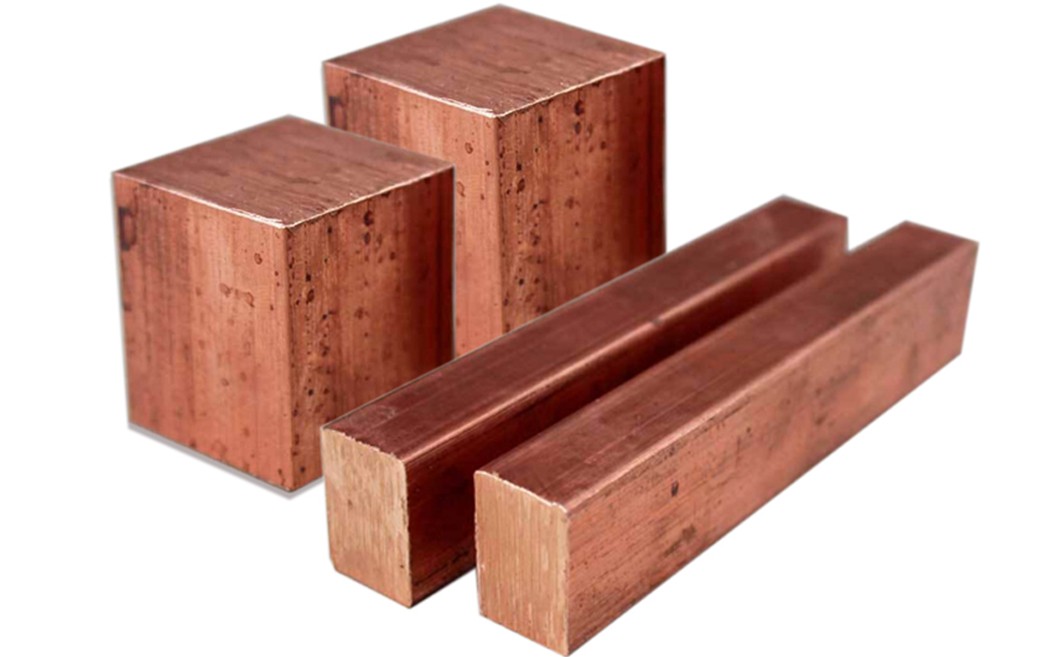

Brass is an alloy of copper and zinc. It has high strength and excellent machinability and wear resistance. The surface of brass will gradually oxidize and turn black in the air, but it will form an oxide film to protect the interior. It is often used in the manufacture of precision instruments, ship parts, auto parts, medical accessories, electrical accessories, industrial products and other precision copper parts.

It is a thermoplastic polymer structural material with high strength, good toughness and easy processing. It is also a low-cost engineering plastic with good processing performance, strong mechanical properties, and a wide range of applications, making it an excellent choice for production parts.

Titanium (titanium alloy) is a structural metal with light weight, high strength, good corrosion resistance and high heat resistance. Commonly used in automotive industry, aviation fasteners, turbine blades, engine parts, sports equipment, marine, environmental protection and other applications.

It has the characteristics of high strength, high rigidsity, low density and wear resistance. It is the lightest metal among practical metals, it has high stability, high dimensional accuracy, and can be machined with high precision.

It is a thermoplastic polymer structural material with high strength, good toughness and easy processing. It is also a low-cost engineering plastic with good processing performance, strong mechanical properties, and a wide range of applications, making it an excellent choice for production parts.

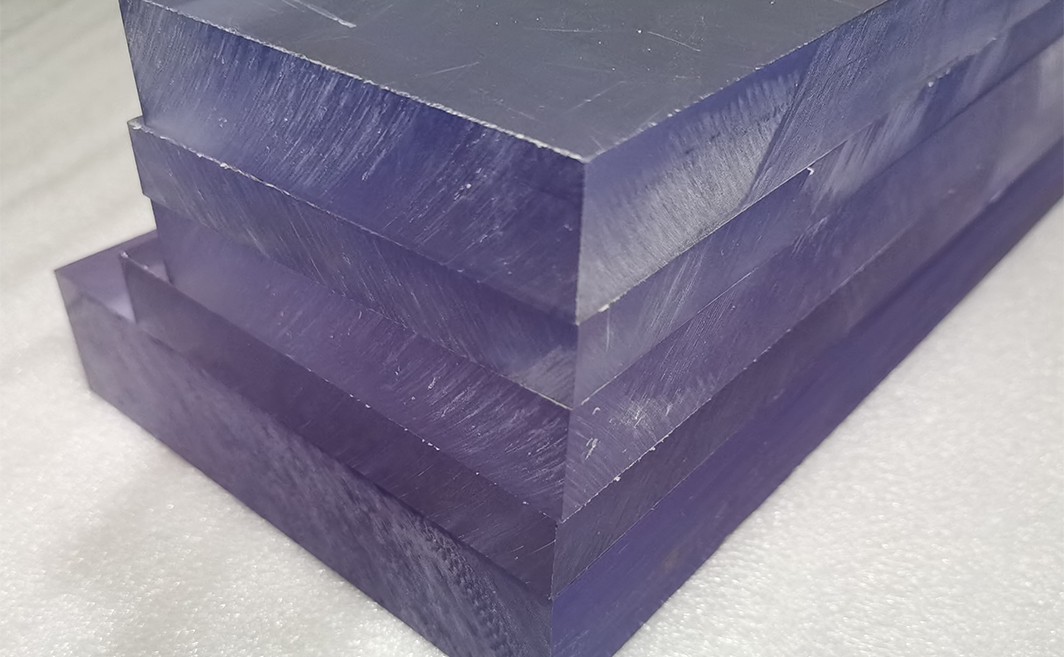

Polycarbonate, referred to as PC engineering plastics, an amorphous thermoplastic resin with excellent comprehensive properties, an engineering plastic with excellent electrical insulation, ductility, dimensional stability and chemical resistance, high strength and weather resistance.

Nylon(PA). Also known as polyamide

It is the most important engineering plastic, covering almost every application field, widely used in chemical machinery, anti-corrosion equipment gear and parts blanks, transmission structural parts, household appliance parts, auto parts, etc.

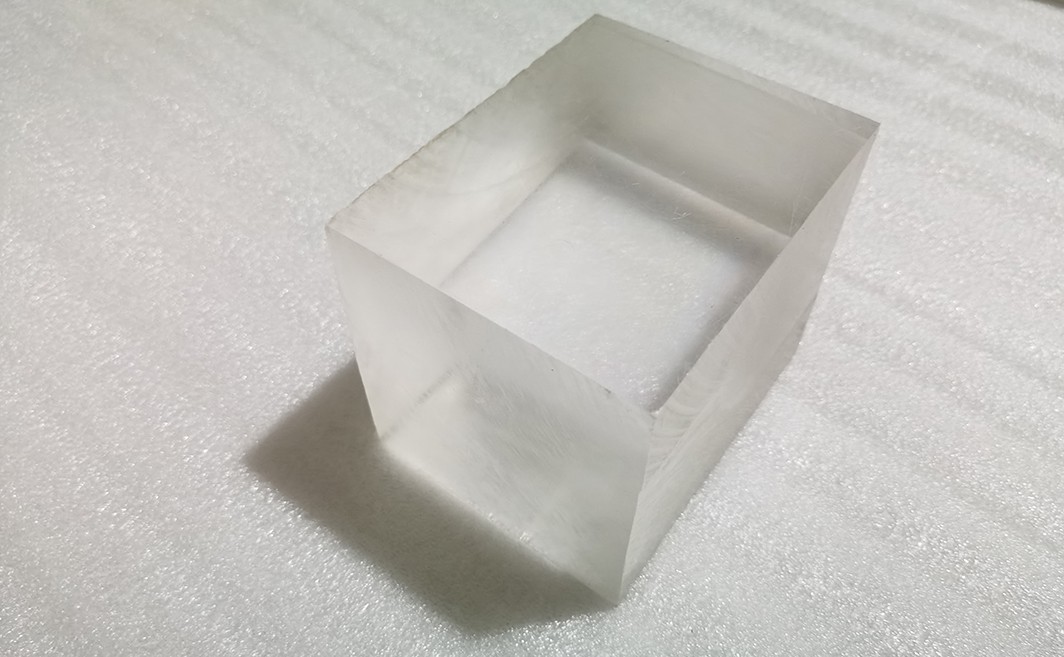

PMMA:(polymethyl methacrylate)Also known as acrylic

It has the characteristics of good transparency, chemical stability and weather resistance, easy dyeing, easy processing, good plasticity and beautiful appearance. It is widely used in medical, industry, automobile and other fields. However, its thin-walled areas are fragile during machining, so it is not recommended for delicate or complex geometries.

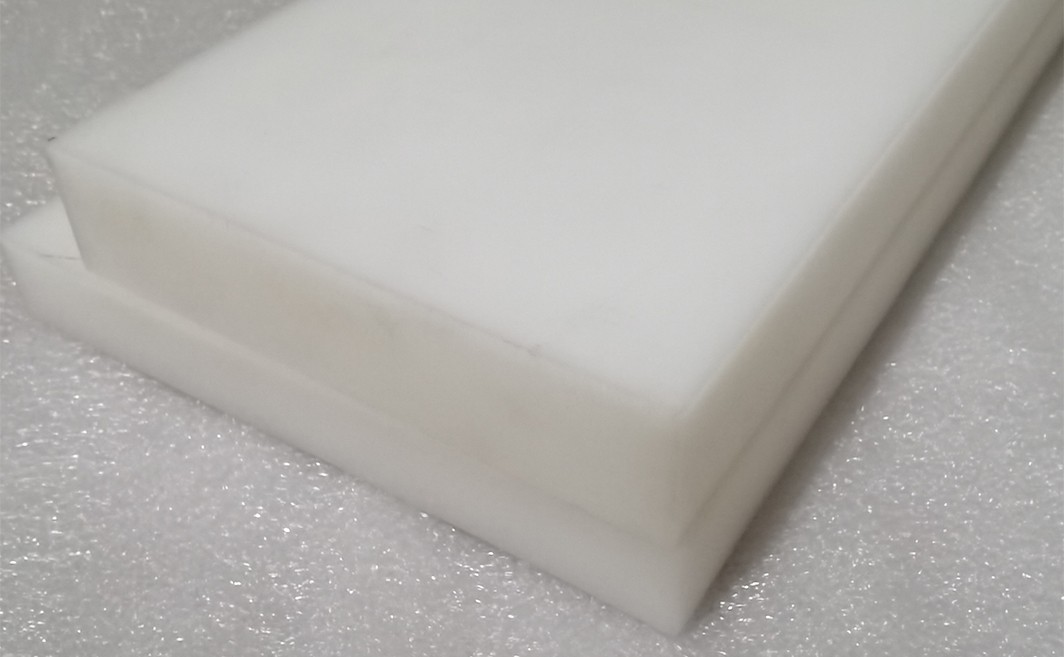

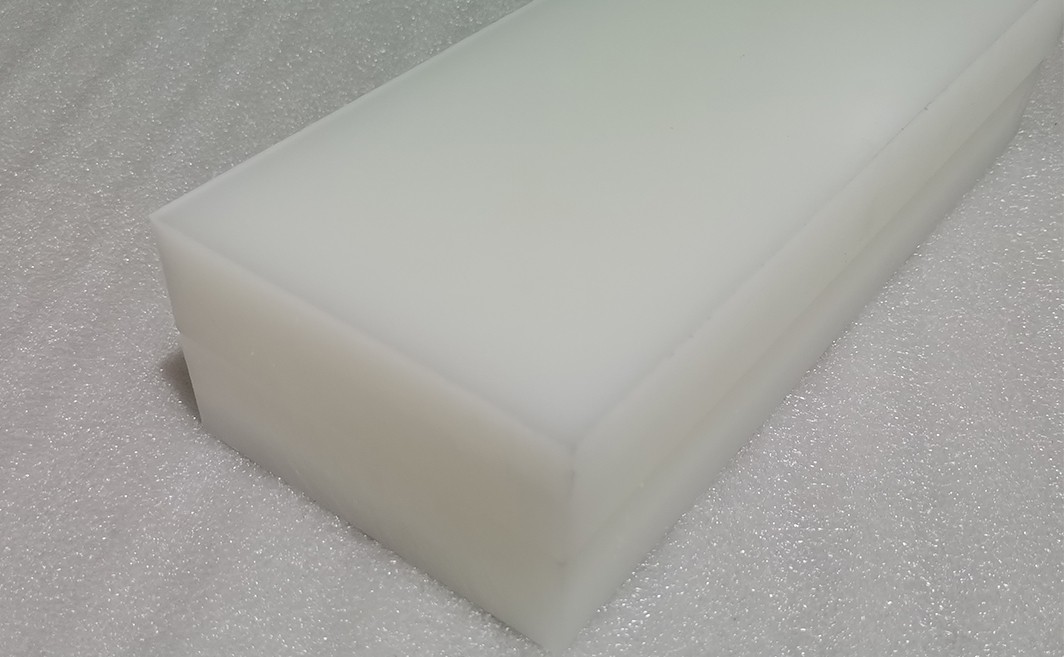

POM (polyformaldehyde) is an engineering plastic with high hardness, high rigidity and high wear resistance. It has good surface hardness and compactness, and is suitable for gears, bearings, auto parts, machine tools, instrument internals and other products that play a skeleton role.

PEEK (poly-ether-ether-ketones) is a high-performance specialty engineering plastic that is an excellent lightweight alternative to most soft metals. It has excellent mechanical properties, good self-lubrication, chemical resistance, and good wear resistance. Commonly used in aerospace, automobile manufacturing, electrical and electronic, medical, and other fields.

It is one of the lightest varieties of all plastics at present; it has the characteristics of high heat resistance, good mechanical properties, environmental protection and non-toxicity. It is suitable for making general mechanical parts, corrosion-resistant parts and insulating parts.

Commonly known as "Plastic King", it has excellent properties such as high and low temperature resistance, chemical corrosion resistance, small friction coefficient, self-lubrication and non-stickiness. Widely used in aerospace, electronics, electrical, chemical, machinery and other industries.

The gear production line is fully equipped, such as: turning, hobbing, shaving, grinding, shaping, grinding and other gear processing processes using imported CNC equipment: Japanese Lonze lathe, Mitsubishi hobbing machine (with automatic loading and unloading), German E Mark Kopfer gear hobbing machine (with automatic loading and unloading), German Liebherr CNC gear shaping machine, Leishauer CNC gear grinding machine, German DMG DMG horizontal machining center (with 5 worktables), etc. The testing room is equipped with various precision testing equipment such as: Japan Mitutoyo Measurement items such as boremeter, height meter, runout meter, gear inspection center, and Hexagon three-dimensional coordinate inspection center include gear tooth shape, tooth direction, pitch, runout, common normal, etc., and the measurement accuracy can reach ISO level 1.

Quote Now