Our inspection instruments include German Zeiss CMM, Wanhao image measuring instrument, Hitachi handheld spectrometer, Mitutoyo roughness measuring instrument, etc.

AARS Smart Tech. was full certificated by ISO9001:2015, IATF16949:2016.

According to the regulations of AARS Smart Tech. , all data are managed by special personnel to ensure information security in all aspects.

We have advanced high precision equipment like Germany GROB 5 axis machine, Swiss GF Mikron 5 axis machine, China Jingdiao 5 axis machine and US Haas 4 axis machine, tolerance down to +/-0.0015 mm.

CNC milling is one of the most common process methods, used in processing designs of all sizes. Raw materials will be feed into the milling center which cuts the excess away. The raw material was selected and measured to produce minimum waste, reducing production cost. AARS Smart Tech. use the latest CNC machine and controls to produce your design quick and precision. Here are our CNC milling capabilities.

Maximum depth that can be milled is 2 in. (50.8mm) from either side of part.

Typically, AARS Smart Tech. can hold a machining tolerance of +/-0.0002 in(0.005 mm) . Part features are recommended to be thicker than 0.020 in. (0.51mm) in all regions and a nominal part thickness above 0.040 in.

Sharp inside corners on a part will be radiused (rounded) as a natural result of the CNC machining process. Resulting Radius will be identified on your quote.

According to the processing requirements of different parts and the special materials, the maximum processing depth of the hole can reach 350mm.

It is the most widely used non-ferrous metal structural material in the industry. As a soft, lightweight and durable metal material, it is often used in aerospace, automobile, machinery manufacturing, shipbuilding and industrial development. The customized aluminum products processed by AARS Smart Tech. have a wide range of appearance and color options and a complete range of surface treatments, which can meet the needs of different industries.

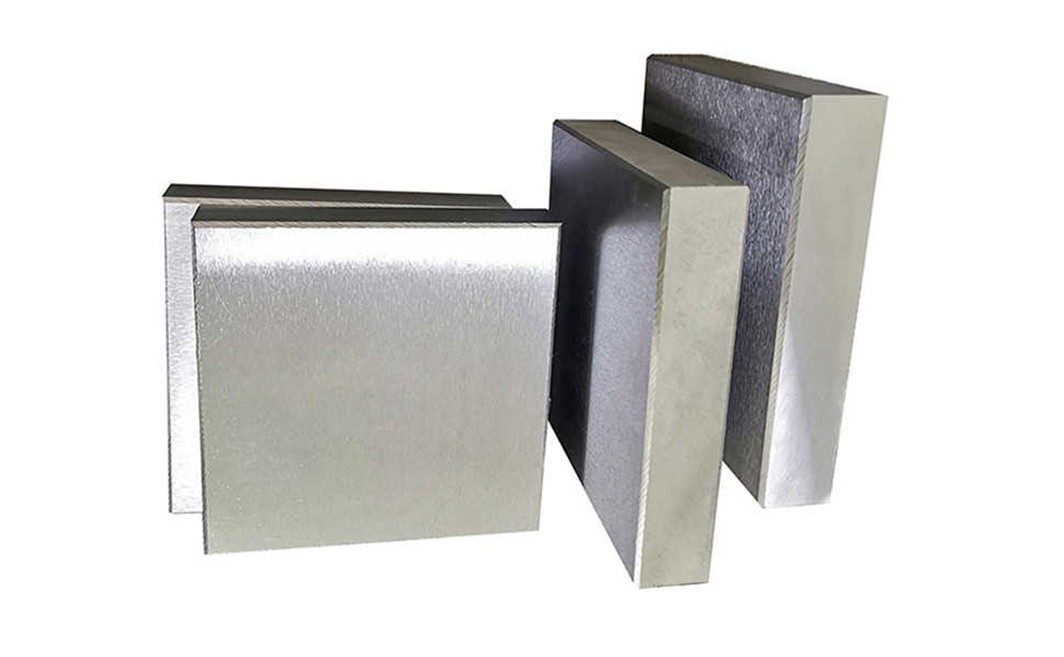

Stainless steel has the characteristics of corrosion resistance, high temperature resistance and ultra-low temperature resistance.It has a wide range of applications and can be used to manufacture medical equipment, auto parts, industrial products, etc. DADESIN can provide a variety of stainless steels such as 201, 202, 303, 304, 316, 4130, 4140.

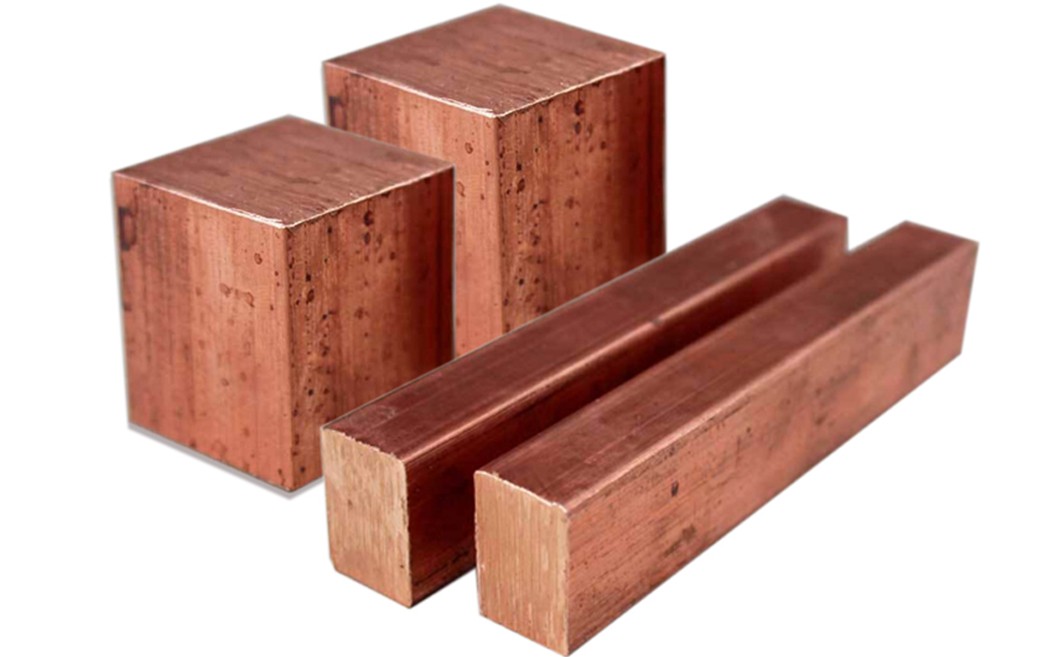

Brass is an alloy of copper and zinc. It has high strength and excellent machinability and wear resistance. The surface of brass will gradually oxidize and turn black in the air, but it will form an oxide film to protect the interior. It is often used in the manufacture of precision instruments, ship parts, auto parts, medical accessories, electrical accessories, industrial products and other precision copper parts.

It is a thermoplastic polymer structural material with high strength, good toughness and easy processing. It is also a low-cost engineering plastic with good processing performance, strong mechanical properties, and a wide range of applications, making it an excellent choice for production parts.

Titanium (titanium alloy) is a structural metal with light weight, high strength, good corrosion resistance and high heat resistance. Commonly used in automotive industry, aviation fasteners, turbine blades, engine parts, sports equipment, marine, environmental protection and other applications.

It has the characteristics of high strength, high rigidsity, low density and wear resistance. It is the lightest metal among practical metals, it has high stability, high dimensional accuracy, and can be machined with high precision.

It is a thermoplastic polymer structural material with high strength, good toughness and easy processing. It is also a low-cost engineering plastic with good processing performance, strong mechanical properties, and a wide range of applications, making it an excellent choice for production parts.

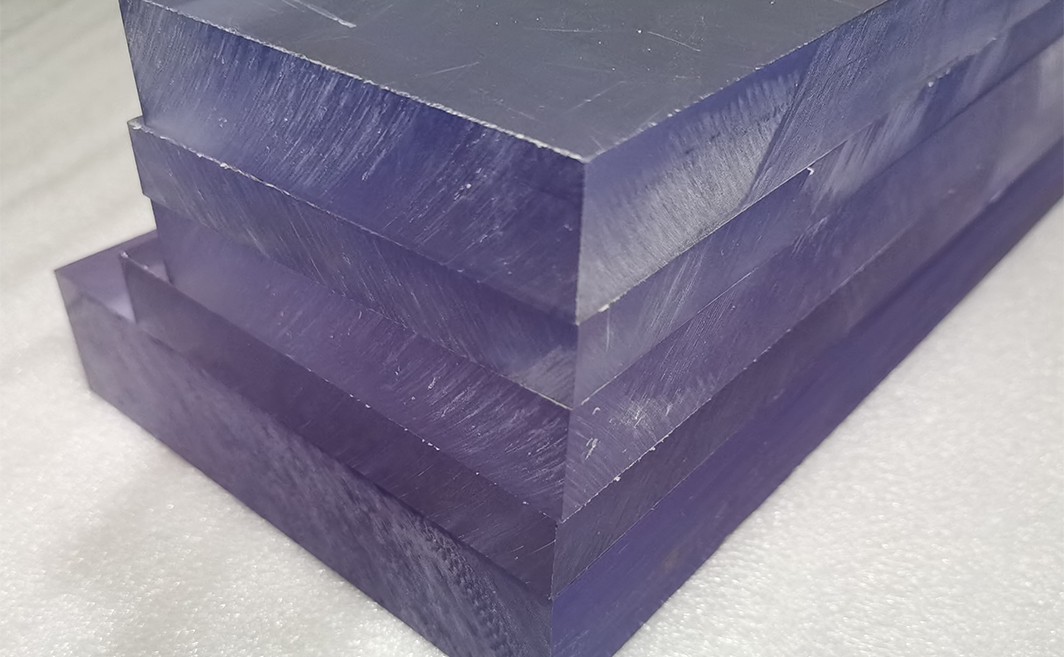

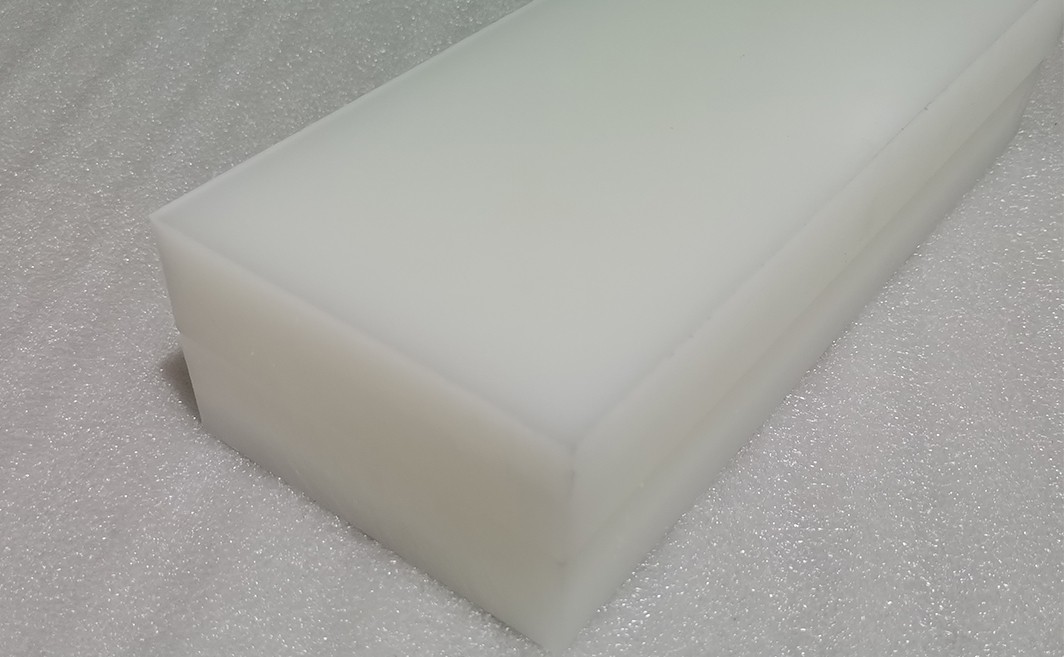

Polycarbonate, referred to as PC engineering plastics, an amorphous thermoplastic resin with excellent comprehensive properties, an engineering plastic with excellent electrical insulation, ductility, dimensional stability and chemical resistance, high strength and weather resistance.

Nylon(PA). Also known as polyamide

It is the most important engineering plastic, covering almost every application field, widely used in chemical machinery, anti-corrosion equipment gear and parts blanks, transmission structural parts, household appliance parts, auto parts, etc.

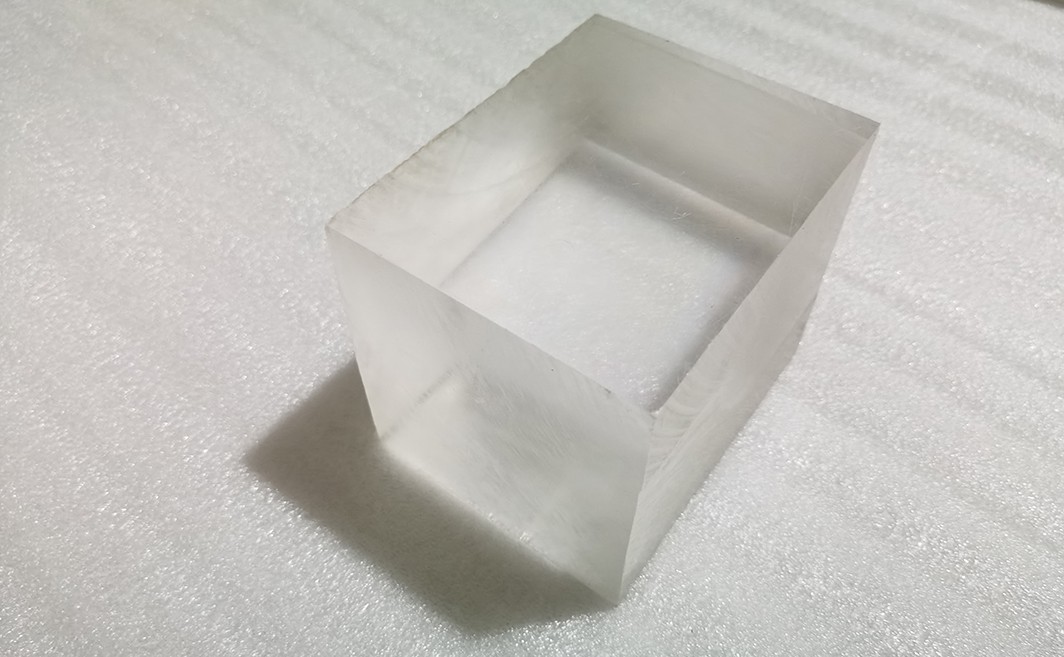

PMMA:(polymethyl methacrylate)Also known as acrylic

It has the characteristics of good transparency, chemical stability and weather resistance, easy dyeing, easy processing, good plasticity and beautiful appearance. It is widely used in medical, industry, automobile and other fields. However, its thin-walled areas are fragile during machining, so it is not recommended for delicate or complex geometries.

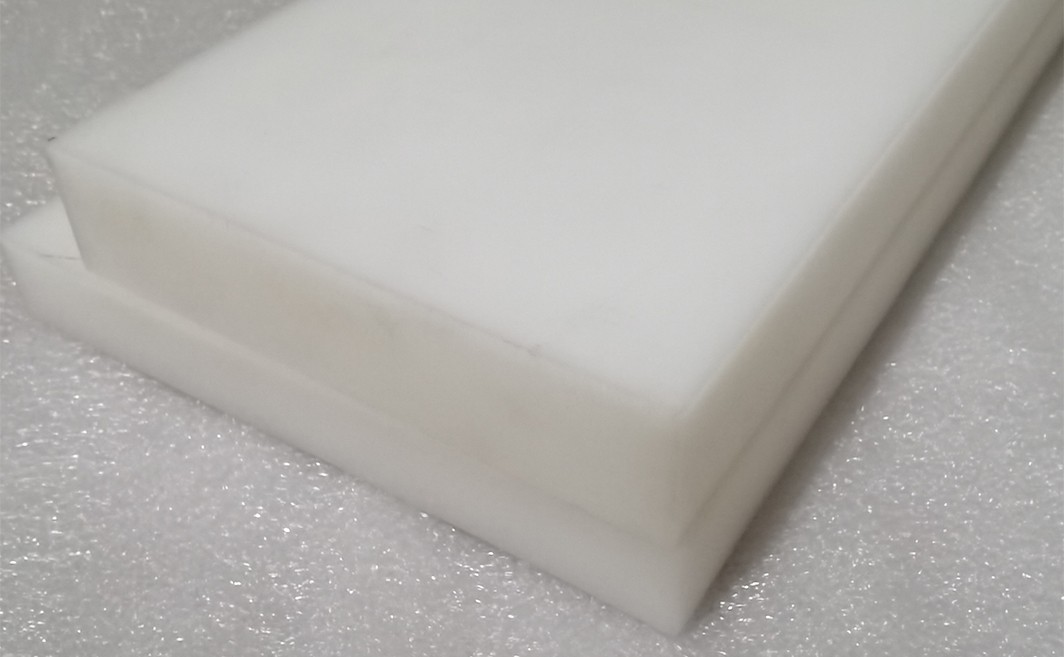

POM (polyformaldehyde) is an engineering plastic with high hardness, high rigidity and high wear resistance. It has good surface hardness and compactness, and is suitable for gears, bearings, auto parts, machine tools, instrument internals and other products that play a skeleton role.

PEEK (poly-ether-ether-ketones) is a high-performance specialty engineering plastic that is an excellent lightweight alternative to most soft metals. It has excellent mechanical properties, good self-lubrication, chemical resistance, and good wear resistance. Commonly used in aerospace, automobile manufacturing, electrical and electronic, medical, and other fields.

It is one of the lightest varieties of all plastics at present; it has the characteristics of high heat resistance, good mechanical properties, environmental protection and non-toxicity. It is suitable for making general mechanical parts, corrosion-resistant parts and insulating parts.

Commonly known as "Plastic King", it has excellent properties such as high and low temperature resistance, chemical corrosion resistance, small friction coefficient, self-lubrication and non-stickiness. Widely used in aerospace, electronics, electrical, chemical, machinery and other industries.

Our improved algorithm reduces Rapid Prototyping quote time by 90%, with most quotes delivered within 24 hours, depending on project details. Your customer support partner will contact you directly with your Rapid Prototyping quote to ensure